ANDO Laboratory

Research

Latest research

Environmental problems troubling the world are not only global warming, but also microplastics (MPs) drifting in the sea. Since it absorbs harmful chemical substances such as dioxins and polychlorinated biphenyls (PCBs), there is concern that it will adversely affect not only fish and animals, but also humans through the food chain. On the other hand, there is a large amount of plastic products in our lives, and it is difficult to eliminate plastic from society.

Woody biomass, which is the most abundant resource on earth, is a recyclable material that uses photosynthesis. Even woody biomass is discarded in large quantities, such as vegetable oil extraction slag and bamboo, which propagates at a high rate and erodes forests and causes disasters such as landslides. Woody biomass, which is difficult to manage, has become a regional issue. In order to reduce such waste, the use of non-edible woody biomass is gradually expanding. The composition ratio and molecular weight of hemicellulose, cellulose, and lignin, which are the main components of woody biomass, differ depending on the type of plants. Therefore, in order to use woody biomass as a material, it is necessary to extract each component and develop its application.

Our laboratory is conducting research to develop materials that use woody biomass as a feedstock in order to solve the regional issues. For example, there has been an establishment of basic technology for the utilization of cellulose extracted from bamboo and oil palm, as well as the applications development of the derived technology. Fast-growing woody biomass, such as bamboo and oil palm, is photosynthetically active and can be regarded as a material in which a large amount of CO2 is consumed. By increasing the social and commercial-added value of bamboo as a CO2 fixing material, it is possible to solve local issues and create a consumption chain from bamboo collection to utilization and regeneration using photosynthesis. As a result, it can be expected to create an environmentally harmonious zero-carbon cycle that is good for local businesses, the local environment and the local community in three ways.

Based on the technology to separate and extract constituent materials such as cellulose and lignin in environmentally low-impact reactions, research is being undertaken to add value to the materials obtained from them.

Sustainable materials

Features: Eco-friendly polymer design

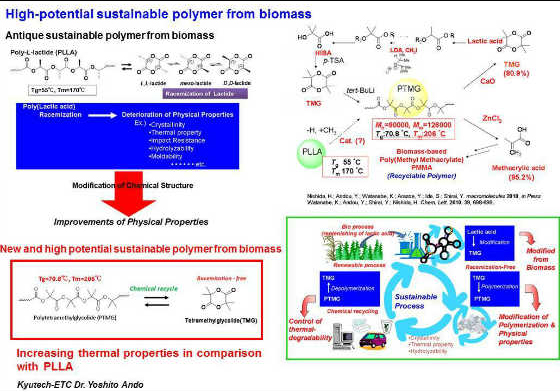

Poly-L-lactic acid (PLLA), which is one of the typical bioplastics, is made from fermented product L-lactic acid and has excellent chemical recyclability, so it is known as a resource-recycling material. The physical characteristics of PLLA are similar to those of general-purpose resins such as polystyrene and polyethylene terephthalate, and since they are biocompatible and biodegradable, which are unique to fermented products, their widespread use is expected.

However, PLLA has problems in heat resistance and impact resistance as compared with general-purpose resins derived from petroleum, and since its physical characteristics depend on optical purity, structural isomerization (racemization) occurs at high temperatures. As it progresses, the physical properties are likely to deteriorate significantly.

Therefore, in order to overcome the problems of PLLA from the viewpoint of basic chemical structure, the methine hydrogen of PLLA was replaced with a methyl group to induce the optically inactive polytetramethylglycolide (PTMG). Using fermented products pyruvic acid and lactic acid as raw materials, they were induced to HIBA by a chemical method, which led to PTMG synthesis, and their resource recycling characteristics were clarified. Furthermore, we are expanding to biomass-derived polymethyl methacrylate (PMMA).

Gas-phase polymerization

Environmentally friendly surface modification method

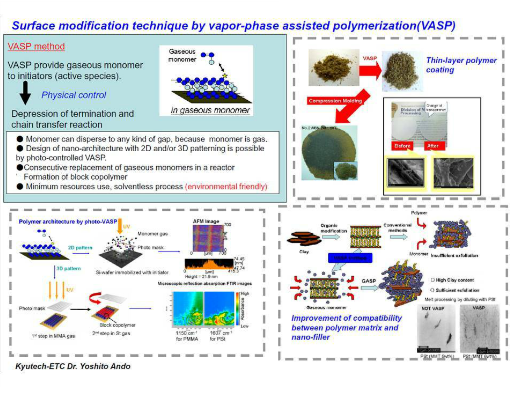

The gas phase polymerization method gasifies the monomer and organic reagent, easily diffuses the monomer and organic reagent into the microstructure space of the substrate, and allows the substrate with a complicated surface to react on the surface. It is a polymerization method. In addition, since no solvent is used, the environmental burden is small. Surface coating can be done with the minimum amount of monomer used.

For example, a masterbatch of a polymer composite material having a high biomass content can be prepared. Therefore, by finely coating the biomass material using the vapor phase method, it is possible to control the surface properties, increase the affinity between the biomass and the plastic material, and facilitate the composite.

What is interesting is that information on the construction of a new interface structure different from the conventional liquid phase method can be obtained at the interface between the surface of the substrate and the adsorption of monomers.

Functional materials using natural materials

Effective use of biomass

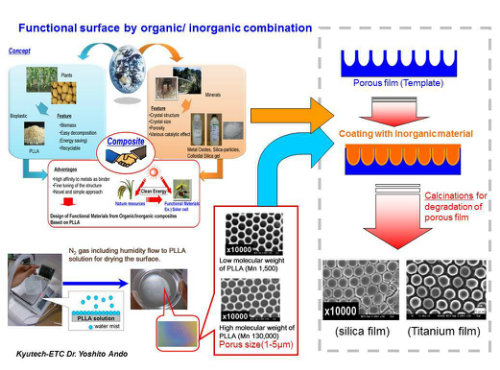

We also tried to create a porous membrane using biomass-derived materials for amphipathic materials. As an approach from the aspect of high functionality, we focused on the application to honeycomb-like porous membranes obtained by self-assembly in a high humidity atmosphere. The amphipathic material in solution plays an important role in the process of forming the porous membrane produced by this method. So far, random copolymers, block copolymers, polyion complexes and the like have been used as amphipathic materials.

However, by using lecithin derived from soybean, a porous membrane as shown in the figure could be obtained. The effects on the formation of the porous membrane, such as the difference in gas flow rate, substrate temperature, and molecular weight of polylactic acid, were also examined.

In addition, using the obtained porous membrane as a template, applying inorganic fine particles, and then sintering at 400 ° C, an inorganic material thin film was obtained, and we found out that its structure was greatly affected by the molecular weight of the polymer used.

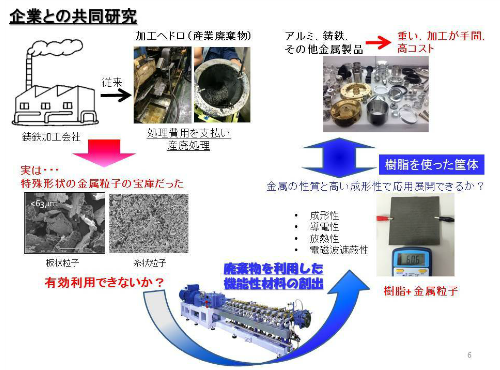

Functional materials using waste

Environmentally symbiotic functional material

By specially treating the waste discharged from the metal processing factory, we have succeeded in easily recovering the metal fine particles and using them as a metal filler. By combining with various polymer materials, we succeeded in creating a material with many useful functions such as thermal conductivity, conductivity, and electromagnetic wave shielding property.